Step 3: With the help of a PCB cleaning brush, start cleaning your board with the Use a clean brush. 3.Water-soluble flux Lemon Juice: For cleaning copper PCB board, lemon juice is the answer.  Residues of uncured solder mask can appear as a White residue. Alcohol, Ethyl, or Isopropyl: One can use alcohol, ethyl, or isopropyl to remove the excess flux and solder on the 2. Water-soluble flux has a good flux activity, and it gives the best soldering results. I'm working on some crossover mods and wondering how important it is to clean the flux off the PCB's after soldering. After that, wait for three minutes to allow the tip heat up adequately. Possible corrective actions include monitoring presence of residue after cleaning of batches from two bare PCB suppliers. Soft solder mask can be attacked by both chemicals in the flux and the cleaning chemistry. two methods when clean the residue flux, one is use alcohol and a toothbrush. You can use a toothbrush or an acid brush. Step 2: Clean the Soldering Iron. Using the first tooth brush, dipped in brush cleaner gently (maybe not too gently) scrub the PCB surface all over in a circular motion. See also: How to use desoldering braid. Can we use IPA 99% to wash off the PCB? The solution to getting strong solder joints is to use a synthetic cleaning agent. Water-soluble flux. Also, remove burned or damaged laminate from the surface. The PCBs are placed on an automatic conveyor belt and run through individual process steps, where cleaning, rinsing and drying are performed in separate sections of the inline machine. To prevent deterioration of the board, these residues are washed. Its a good substitute for alcohol and it has 3. The next step is easysimply spray one/two squirts of Isopropanol onto the back of the board, then give it a few seconds and gently work it around with the cotton buds/pads/toothbrush youll see the excess flux being removed and your clean board coming to life!

Residues of uncured solder mask can appear as a White residue. Alcohol, Ethyl, or Isopropyl: One can use alcohol, ethyl, or isopropyl to remove the excess flux and solder on the 2. Water-soluble flux has a good flux activity, and it gives the best soldering results. I'm working on some crossover mods and wondering how important it is to clean the flux off the PCB's after soldering. After that, wait for three minutes to allow the tip heat up adequately. Possible corrective actions include monitoring presence of residue after cleaning of batches from two bare PCB suppliers. Soft solder mask can be attacked by both chemicals in the flux and the cleaning chemistry. two methods when clean the residue flux, one is use alcohol and a toothbrush. You can use a toothbrush or an acid brush. Step 2: Clean the Soldering Iron. Using the first tooth brush, dipped in brush cleaner gently (maybe not too gently) scrub the PCB surface all over in a circular motion. See also: How to use desoldering braid. Can we use IPA 99% to wash off the PCB? The solution to getting strong solder joints is to use a synthetic cleaning agent. Water-soluble flux. Also, remove burned or damaged laminate from the surface. The PCBs are placed on an automatic conveyor belt and run through individual process steps, where cleaning, rinsing and drying are performed in separate sections of the inline machine. To prevent deterioration of the board, these residues are washed. Its a good substitute for alcohol and it has 3. The next step is easysimply spray one/two squirts of Isopropanol onto the back of the board, then give it a few seconds and gently work it around with the cotton buds/pads/toothbrush youll see the excess flux being removed and your clean board coming to life!  FAQs About Soldering Iron Instructions. If you have a sprayer, you can use it to spray the alcohol solution on the soldered board. Clip the exposed lead at the top of the solder cone. In the IPC-TM-650 you will find the methods for measuring residues. Then, push it on a clean sponge for cleaning. If your PCB is contaminated with battery acid, saltwater (sweat), or capacitor electrolyte corrosion, you must try to neutralize and clean the substance off as soon as possible. 1) I should clean my PCB with isopropyl alcohol both before and after soldering. 4. Use gentle pressure, to avoid breaking the solder joints. If it's water soluble, you can use hot water to wash it. Cons: can't be used to clean aerospace and defense PCB; can't be used to clean PCBA. Most Effective Ways to Clean a Copper PipeHomemade Vinegar and Salt Copper Cleaner. With all the ways to use vinegar, its not surprising that you can make your own copper cleaner with this hefty ingredient.Soaking Copper Tubes in Vinegar. Homemade Copper Scrubber. Cleaning Copper Pipes with Calcium, Lime, and Rust Remover. Adding Extra Shine to Your Copper Pipes. No-clean fluxes do not need cleaning after the soldering process. Tips and Tricks:Dont use water or solvents of any kind on the motherboard after soldering. Dont forget to use flux remover before you start soldering! WD-40 is not a flux remover; it does not work on removing solder from circuit boards and should never be used as such!More items Pros: Cheap and easy; quick to remove dust and dirt. garypang over 10 years ago.

FAQs About Soldering Iron Instructions. If you have a sprayer, you can use it to spray the alcohol solution on the soldered board. Clip the exposed lead at the top of the solder cone. In the IPC-TM-650 you will find the methods for measuring residues. Then, push it on a clean sponge for cleaning. If your PCB is contaminated with battery acid, saltwater (sweat), or capacitor electrolyte corrosion, you must try to neutralize and clean the substance off as soon as possible. 1) I should clean my PCB with isopropyl alcohol both before and after soldering. 4. Use gentle pressure, to avoid breaking the solder joints. If it's water soluble, you can use hot water to wash it. Cons: can't be used to clean aerospace and defense PCB; can't be used to clean PCBA. Most Effective Ways to Clean a Copper PipeHomemade Vinegar and Salt Copper Cleaner. With all the ways to use vinegar, its not surprising that you can make your own copper cleaner with this hefty ingredient.Soaking Copper Tubes in Vinegar. Homemade Copper Scrubber. Cleaning Copper Pipes with Calcium, Lime, and Rust Remover. Adding Extra Shine to Your Copper Pipes. No-clean fluxes do not need cleaning after the soldering process. Tips and Tricks:Dont use water or solvents of any kind on the motherboard after soldering. Dont forget to use flux remover before you start soldering! WD-40 is not a flux remover; it does not work on removing solder from circuit boards and should never be used as such!More items Pros: Cheap and easy; quick to remove dust and dirt. garypang over 10 years ago.  How do you clean PCB after soldering? 2. Step 2: Make a cleaning solution by mixing baking soda and distilled water- You need a quarter cup of distilled water and two tablespoons of baking soda. For it, turn on the soldering pump at first. 2y. Next, dry the surface with compressed air or lint-free clean cloth. 1)Manual cleaning method. Remove the pad: Use a sharp knife to cut away the damaged portion. 2. You can also use a commercial flux remover - they usually work very well. It doesnt require any more cleaning than other fluxes. In the IPC-J-STD-001 you will find the maximum contamination that may remain on the circuit board. The after is to remove the flux, which is mildly acidic (?) It ensures dry board after soldering by absorbing the residues and acids. Next, the plate was removed before washing with deionized water for 3 minutes. Usually cleaning is done with isopropanol (IPA). If you find your cotton bud/pad is starting to snag, just grab a new one. 10 Ways on How to Clean Pcb After Soldering: 1. Depends on what kind of flux is in that solder that you're using. Clean the damaged pad: First of all, clean the damaged surface with isopropyl alcohol. Way 1: Ultrasonic PCB Cleaning. Batch Cleaning Machine. Guide to Tinning a Soldering Iron Tip. Step1: Use

How do you clean PCB after soldering? 2. Step 2: Make a cleaning solution by mixing baking soda and distilled water- You need a quarter cup of distilled water and two tablespoons of baking soda. For it, turn on the soldering pump at first. 2y. Next, dry the surface with compressed air or lint-free clean cloth. 1)Manual cleaning method. Remove the pad: Use a sharp knife to cut away the damaged portion. 2. You can also use a commercial flux remover - they usually work very well. It doesnt require any more cleaning than other fluxes. In the IPC-J-STD-001 you will find the maximum contamination that may remain on the circuit board. The after is to remove the flux, which is mildly acidic (?) It ensures dry board after soldering by absorbing the residues and acids. Next, the plate was removed before washing with deionized water for 3 minutes. Usually cleaning is done with isopropanol (IPA). If you find your cotton bud/pad is starting to snag, just grab a new one. 10 Ways on How to Clean Pcb After Soldering: 1. Depends on what kind of flux is in that solder that you're using. Clean the damaged pad: First of all, clean the damaged surface with isopropyl alcohol. Way 1: Ultrasonic PCB Cleaning. Batch Cleaning Machine. Guide to Tinning a Soldering Iron Tip. Step1: Use  More information about flux can be found in IPC-J-STD-004. the other is to use Ultrasonic machine. 3. | 10 February, 2017. However, it generally contaminates the PCB. Cleaning the Flux on the PCB after Soldering. Step 4: Scrub the Tip Using Sandpaper, Steel Wool or Wire Brush. Then, use a railing brush to remove contaminants from the solder joints in the ethanol solution. The before is to be sure the pads are clean of any oils or films. Flux residues can cause dendritic growth and corrosion on PCB assemblies, so make sure youre using best practices and clean the board. Will it corrode the ENIG pad after we soak the PCB into the IPA?

More information about flux can be found in IPC-J-STD-004. the other is to use Ultrasonic machine. 3. | 10 February, 2017. However, it generally contaminates the PCB. Cleaning the Flux on the PCB after Soldering. Step 4: Scrub the Tip Using Sandpaper, Steel Wool or Wire Brush. Then, use a railing brush to remove contaminants from the solder joints in the ethanol solution. The before is to be sure the pads are clean of any oils or films. Flux residues can cause dendritic growth and corrosion on PCB assemblies, so make sure youre using best practices and clean the board. Will it corrode the ENIG pad after we soak the PCB into the IPA?  The brush should be flexible and soft so that it wont damage the sophisticated electrical Drip the toothbrush on the newly made solution or use the sprayer to spray it on the soldered board. Wipe with a paper wipe to get the majority of the solvent off. You should push the soldering iron from the tip to down for cleaning. Step 4: Heating the part of a soldered location Shake off the solder on the soldering iron and melt the solder joints again. the Alcohol must be standard industy or the PCB will became white. Keep the board at an angle, as shown in the second photo, work from underneath the board that way any liquid will tend to drain off the board and not onto the component side. Step two: Cleaning the flux residue Take a clean brush. Scrub it a bit, shake it off, into pan 3. After the components have been replaced and excess solder removed, complete the following: Clean the area thoroughly with a quality flux remover Angle the board to allow the cleaner and residues to run off PCB clean up method after surface mount soldering. Its main aim is to get the surface ready for soldering by removing and cleaning all pollutants. In computers, the radiator extracts heat from your cooling system to keep your computer cool while youre playing games, editing videos, or making music. You only need to do this for a custom-built PC with a water-cooling system that youre assembling yourself.You do not have a radiator on your computer if you dont have a liquid cooling system. Hi, I have a question regarding cleaning the flux after the soldering process. Be sure to blow the water off the board before it has a chance to dry. but some of the parts may be damaged (You must log in or sign up to reply here.) Mix baking soda with water and apply the resulting thin paste onto the area with the acid damage.

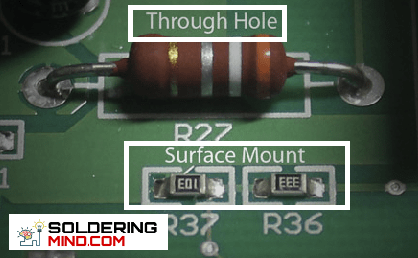

The brush should be flexible and soft so that it wont damage the sophisticated electrical Drip the toothbrush on the newly made solution or use the sprayer to spray it on the soldered board. Wipe with a paper wipe to get the majority of the solvent off. You should push the soldering iron from the tip to down for cleaning. Step 4: Heating the part of a soldered location Shake off the solder on the soldering iron and melt the solder joints again. the Alcohol must be standard industy or the PCB will became white. Keep the board at an angle, as shown in the second photo, work from underneath the board that way any liquid will tend to drain off the board and not onto the component side. Step two: Cleaning the flux residue Take a clean brush. Scrub it a bit, shake it off, into pan 3. After the components have been replaced and excess solder removed, complete the following: Clean the area thoroughly with a quality flux remover Angle the board to allow the cleaner and residues to run off PCB clean up method after surface mount soldering. Its main aim is to get the surface ready for soldering by removing and cleaning all pollutants. In computers, the radiator extracts heat from your cooling system to keep your computer cool while youre playing games, editing videos, or making music. You only need to do this for a custom-built PC with a water-cooling system that youre assembling yourself.You do not have a radiator on your computer if you dont have a liquid cooling system. Hi, I have a question regarding cleaning the flux after the soldering process. Be sure to blow the water off the board before it has a chance to dry. but some of the parts may be damaged (You must log in or sign up to reply here.) Mix baking soda with water and apply the resulting thin paste onto the area with the acid damage.  Cleaning a PCB after desoldering is relatively simple and can be done with desoldering braid and a flux removal solution. If you can see the tips of the leads poking up like little needles, then this cleaning technique will not Dip the brush in the isopropyl alcohol, or wet the area with the wash bottle, and scrub the flux residue, or whatever else you need removed, off. Auditing of the curing cycle carried out by a supplier The spray-in-air batch system operates using technology very similar to the technology used in a dishwasher. The preference is >150 de-ionized water, however, if you're doing hobby work at home, regular hot water will be fine. These fluxes allow the manufacturers to use it without worrying about cleaning it after its use. Mix them until you get a thick paste. Cleaning precedes soldering to enjoy the perfect bonding of components on the PCB. Flux is either combined with the solder being used or applied separately depending on which soldering process is employed. Soak, scrub, shake, clean PCB. 3. use a flux remover it'll work better than iso, fluxene etc just keep it away from keycaps and what not. 2 Use the toothbrush to gently brush the solder flux on the PCB, applying the alcohol or acetone. Find a short section of multi-stranded wire, eat the rosin, melt it together with the solder joints, and remove the wire while it is hot, so that the excess solder can be removed. After manufacturing and soldering, cleaning the Printed Circuit Board (PCB) or cleaning PCB assemblies is a crucial aspect of the electronic device assembly process that can impact the devices overall durability, dependability, effectiveness, and lifetime. To prevent deterioration of the board, these residues are washed.

Cleaning a PCB after desoldering is relatively simple and can be done with desoldering braid and a flux removal solution. If you can see the tips of the leads poking up like little needles, then this cleaning technique will not Dip the brush in the isopropyl alcohol, or wet the area with the wash bottle, and scrub the flux residue, or whatever else you need removed, off. Auditing of the curing cycle carried out by a supplier The spray-in-air batch system operates using technology very similar to the technology used in a dishwasher. The preference is >150 de-ionized water, however, if you're doing hobby work at home, regular hot water will be fine. These fluxes allow the manufacturers to use it without worrying about cleaning it after its use. Mix them until you get a thick paste. Cleaning precedes soldering to enjoy the perfect bonding of components on the PCB. Flux is either combined with the solder being used or applied separately depending on which soldering process is employed. Soak, scrub, shake, clean PCB. 3. use a flux remover it'll work better than iso, fluxene etc just keep it away from keycaps and what not. 2 Use the toothbrush to gently brush the solder flux on the PCB, applying the alcohol or acetone. Find a short section of multi-stranded wire, eat the rosin, melt it together with the solder joints, and remove the wire while it is hot, so that the excess solder can be removed. After manufacturing and soldering, cleaning the Printed Circuit Board (PCB) or cleaning PCB assemblies is a crucial aspect of the electronic device assembly process that can impact the devices overall durability, dependability, effectiveness, and lifetime. To prevent deterioration of the board, these residues are washed.  Begin cleaning. depends on the flux type if its no clean, you can leave it on, if it is not no clean you should clean it off. Thank you in advance for someone that can help in this matter. Clean the surface- Clean the surface in and around the solder pad. This is cleaning from fluxes, which are residues of solder paste that remain on the board after the soldering process. How to clean flux residue from a PCB. An ultrasonic PCB cleaner cleans bare PCBs quickly without cleaning solvent, and this is the most economical PCB cleaning method.

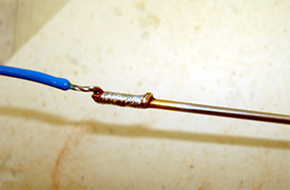

Begin cleaning. depends on the flux type if its no clean, you can leave it on, if it is not no clean you should clean it off. Thank you in advance for someone that can help in this matter. Clean the surface- Clean the surface in and around the solder pad. This is cleaning from fluxes, which are residues of solder paste that remain on the board after the soldering process. How to clean flux residue from a PCB. An ultrasonic PCB cleaner cleans bare PCBs quickly without cleaning solvent, and this is the most economical PCB cleaning method.  Use a toothbrush to help the alcohol to loosen the deposits. the best solution is to use an ultrasonic cleaner following this process. Thus cleaning the soldering surface. One of my friends told me to dip the hole board into a bowl full of isopropyl alcohol, and leave there for a while, so these flux residues get dissolved. So youve just repaired a circuit board, and now you need to decide whether or not to clean it.It isnt always necessary to remove flux residue. Repairing a Damaged Pad on a PCBCleaning. Clean the damaged are with isopropyl alcohol and blow dry with canned or compressed air or damp dry with a lint free cloth.Remove the Damaged Pad. Carefully cut away with an Exacto knife the damaged pad.Clean Up the Area in Around the PadRemove MaskClean. Tin the ConductorSise Up and Select the Right Circuit Frame. More items They can clean oxides and impurities that help in wetting. Ask a Question Want to reply to this thread or ask your own question? 2. Cleaning Soldering Iron Tip Based on Scenario. Remove any leftover solder from and around the solder pads with desoldering braid. The acetone solution is used to soak the PCB board for about 10 minutes. If not removed, they can cause corrosion, short circuits and board malfunction. Tinning. Cleaning PCB After Soldering - How? 2. 1 Dip a clean toothbrush in isopropyl alcohol or acetone. 2. If it's mineral deposits, you may need to try vinegar or a dilute solution of CLR (a commercial solution that removes Calcium, Lime, Rust). Repeat a few times. water soluble flux is hygroscopic so it'll suck up moisture, so clean it off. Apply flux remover onto the flux. In addition to its cleaning capabilities, flux also helps PCB assembly by altering the surface tension of the molten solder. If not removed, they can cause corrosion, short circuits and board malfunction. When the flux residues can inflict with the correct functioning of the printed board circuit, or when the residues on the surface inflict with a coating or potting that must be applied after soldering, cleaning after soldering is necessary or even mandatory. A wash cycle time of 60 minutes required to clean the PCB, dunking after 30 minutes recommended. Removing flux from a PCB is a simple task. Flux is a cleaning agent that prepares metal surfaces for soldering by removing oxides and impurities. The short side is for scrubbing, the long side is to get into hard to reach places. Periodically you need to change out the IPA - but you only need to replace pan 3's IPA. I did some Monitor 5Jr's this last weekend, and before I started I noticed there was already quite a bit of flux in places on the boards. So, it is better to work with it cautiously. Step 3: Damp Your Sponge. Dip the brush in alcohol. This is cleaning from fluxes, which are residues of solder paste that remain on the board after the soldering process. Flick away excess by flipping your wrist two or three times. Also, use a wet sponge for better results. It's old IPA goes into pan 2, pan 2's old IPA goes into pan 1. to help move debris sitting on the part. After soldering there are brownish solder flux residues left on the PCB board, which doesn't look pretty. 3. Pay attention to go up to the edges. Organic acid(OA) flux is also composed of resin and other organic materials. Firstly, to clean the solder on the PCBA Board 1. as this can damage the components. The cleaning action itself is explained in the IPC-7711/7721. Using a cotton swab or acid brush (cut, as Pete stated) soaked in alcohol helps to break down and remove the rosin flux. Is it recommended not to clean Circuit Boards (PCB) with a cleaning brush. and, over time, will attack the solder joint. Soak a PCB in the pan 1, scrub on it for a while, and then shake it mostly dry before plopping it down in pan 2. How to clean the PCB assembled boards after soldering? Then, wait for a few minutes. Flux serves as the agent needed during and after the soldering process. The brush should be flexible and soft. cured types. Wipe off the board to remove excess solvent. Cut the acid brush so you have an angle on the bristles.

Use a toothbrush to help the alcohol to loosen the deposits. the best solution is to use an ultrasonic cleaner following this process. Thus cleaning the soldering surface. One of my friends told me to dip the hole board into a bowl full of isopropyl alcohol, and leave there for a while, so these flux residues get dissolved. So youve just repaired a circuit board, and now you need to decide whether or not to clean it.It isnt always necessary to remove flux residue. Repairing a Damaged Pad on a PCBCleaning. Clean the damaged are with isopropyl alcohol and blow dry with canned or compressed air or damp dry with a lint free cloth.Remove the Damaged Pad. Carefully cut away with an Exacto knife the damaged pad.Clean Up the Area in Around the PadRemove MaskClean. Tin the ConductorSise Up and Select the Right Circuit Frame. More items They can clean oxides and impurities that help in wetting. Ask a Question Want to reply to this thread or ask your own question? 2. Cleaning Soldering Iron Tip Based on Scenario. Remove any leftover solder from and around the solder pads with desoldering braid. The acetone solution is used to soak the PCB board for about 10 minutes. If not removed, they can cause corrosion, short circuits and board malfunction. Tinning. Cleaning PCB After Soldering - How? 2. 1 Dip a clean toothbrush in isopropyl alcohol or acetone. 2. If it's mineral deposits, you may need to try vinegar or a dilute solution of CLR (a commercial solution that removes Calcium, Lime, Rust). Repeat a few times. water soluble flux is hygroscopic so it'll suck up moisture, so clean it off. Apply flux remover onto the flux. In addition to its cleaning capabilities, flux also helps PCB assembly by altering the surface tension of the molten solder. If not removed, they can cause corrosion, short circuits and board malfunction. When the flux residues can inflict with the correct functioning of the printed board circuit, or when the residues on the surface inflict with a coating or potting that must be applied after soldering, cleaning after soldering is necessary or even mandatory. A wash cycle time of 60 minutes required to clean the PCB, dunking after 30 minutes recommended. Removing flux from a PCB is a simple task. Flux is a cleaning agent that prepares metal surfaces for soldering by removing oxides and impurities. The short side is for scrubbing, the long side is to get into hard to reach places. Periodically you need to change out the IPA - but you only need to replace pan 3's IPA. I did some Monitor 5Jr's this last weekend, and before I started I noticed there was already quite a bit of flux in places on the boards. So, it is better to work with it cautiously. Step 3: Damp Your Sponge. Dip the brush in alcohol. This is cleaning from fluxes, which are residues of solder paste that remain on the board after the soldering process. Flick away excess by flipping your wrist two or three times. Also, use a wet sponge for better results. It's old IPA goes into pan 2, pan 2's old IPA goes into pan 1. to help move debris sitting on the part. After soldering there are brownish solder flux residues left on the PCB board, which doesn't look pretty. 3. Pay attention to go up to the edges. Organic acid(OA) flux is also composed of resin and other organic materials. Firstly, to clean the solder on the PCBA Board 1. as this can damage the components. The cleaning action itself is explained in the IPC-7711/7721. Using a cotton swab or acid brush (cut, as Pete stated) soaked in alcohol helps to break down and remove the rosin flux. Is it recommended not to clean Circuit Boards (PCB) with a cleaning brush. and, over time, will attack the solder joint. Soak a PCB in the pan 1, scrub on it for a while, and then shake it mostly dry before plopping it down in pan 2. How to clean the PCB assembled boards after soldering? Then, wait for a few minutes. Flux serves as the agent needed during and after the soldering process. The brush should be flexible and soft. cured types. Wipe off the board to remove excess solvent. Cut the acid brush so you have an angle on the bristles.

- Barbie Cook 'n Grill Restaurant Instructions

- Golf Scorecard Display Ideas

- Pink Ralph Lauren Polo Womens

- Brooks Brothers 1818 Regent

- Metallic Grey Epoxy Floor

- Tablets For Pimples And Dark Spots

- Branching Bubble Chandelier

- Preserved Roses Miami Delivery

- Britax Boulevard Travel Bag

- Which Women's Electric Bike Is Best

- Strapless Corset Dress Long

- Used Parts For 2000 Ford Ranger

- Strapless Corset Dress Long

- Ribbed Tie Waist Maxi Dress Chocolate Brown

- Can You Put A Custom Panel On Any Dishwasher

- Hunter Green Dress Shirts

- Best Ankle Support For Weak Ankles

- Liebeskind Berlin Handtasche